PRESS FEEDER

NC Servo

- High rigidity mechanical structure design and work with Mitsubishi servo control system to ensure the feeding accuracy.

- Friendly operation by adopting Human Machine Interface control.

- Programmable multi-pitch setting function to support the different feeding length and feeding frequency requirement.

- Auto feed monitoring function which can be a safety operation when the unit interlock with press stamping operation.

- Applicable for selecting the optional 4 feeding rolls to meet the thicker material request, to ensure the feeding accuracy.

more information

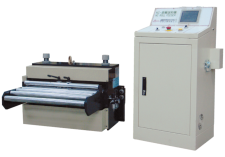

HNC High Speed Servo

- High rigidity mechanical structure design and work with Mitsubishi servo control system to ensure the feeding accuracy.

- Friendly operation by adopting Human Machine Interface control.

- Auto feed monitoring function which can be a safety operation when the unit interlock with press stamping operation.

more information

NC–RL Zig–Zag Servo

- High rigidity mechanical structure design and work with Mitsubishi servo control system to ensure the feeding accuracy.

- Friendly operation by adopting Human Machine Interface control.

- Programmable multi-pitch setting function to support the different feeding length and feeding frequency requirement.

- Auto feed monitoring function which can be a safety operation when the unit interlock with press stamping operation.

- Applicable for selecting the optional 4 feeding rolls to meet the thicker material request, to ensure the feeding accuracy.

- Zig – Zag motion feeding feature is to achieve the material cost saving and that is performing better than the conventional feeders.

- The unit is made under the one-piece body construction design and adopting the linear slide rails, ball screw driving device to achieve the highest working stability.

more information

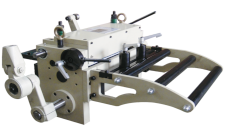

GFS Roll

- Adjustable driving shat designed is to prevent the impact damaged from press while the stamping job is running.

- The feeder is adopting the high precision finishing parts to offer the longest life term for ensuring the stable productivity performance.

- The feeder is capable is capable for 600 S.P.M.under the progressive tooling stamping job.

- Easy adjustment allows working with wide range of material thickness.

- The feeder is driven by press directly,saving the energy and cost for sure.

more information

PRODUCTS